2020 will be memorable. Its already proving to have its own unique challenges. Just when you don’t think it can get much worse something more occurs. We’re strong, we’re resilient, and we’ll get through this…together.

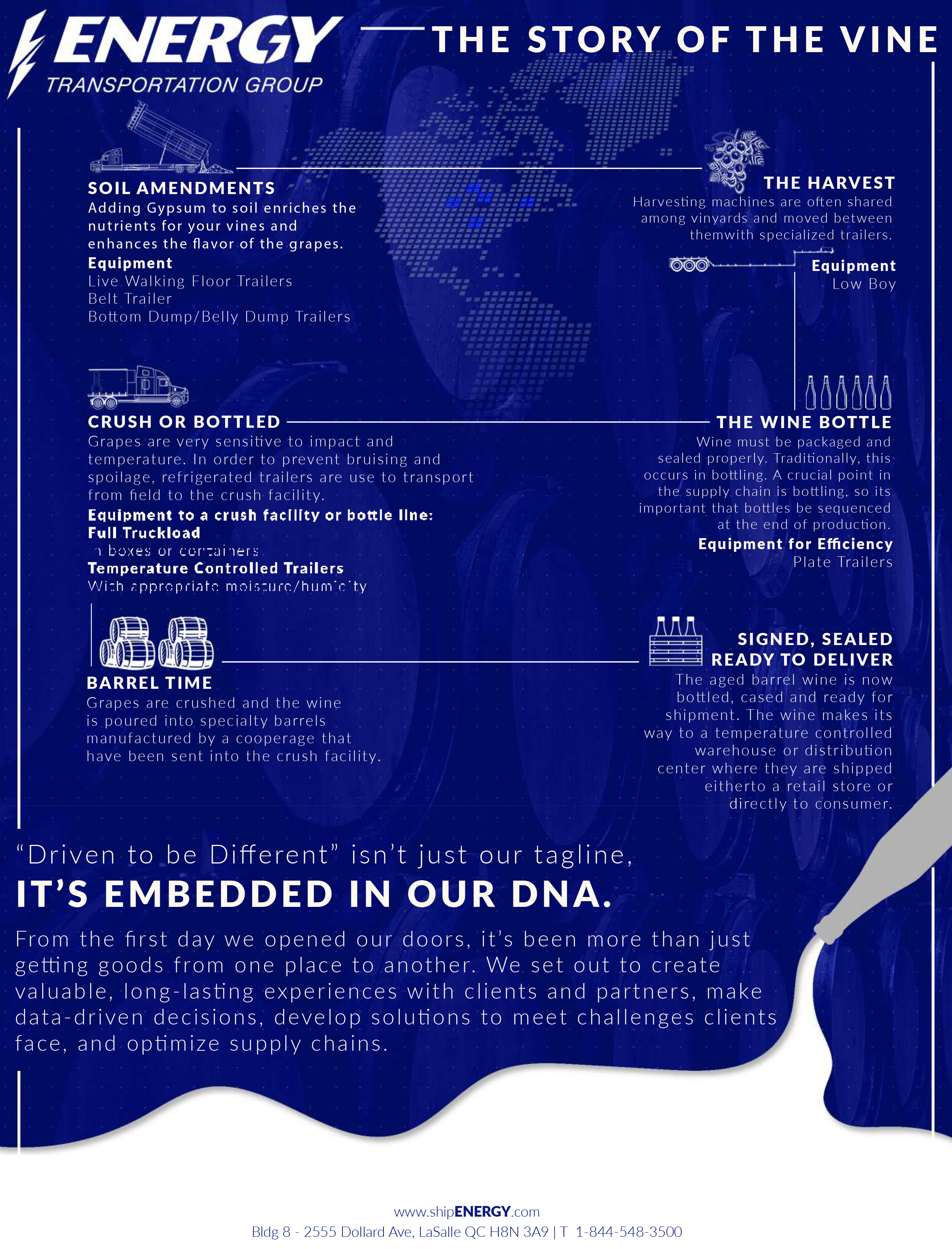

If you’re a buyer, a planner, or in a logistics focused role, you’re likely asking yourself, “What should my supply chain look like post COVID-19?” One of the positive outcomes for businesses connected to alcoholic beverage industry is that in times of uncertainty people tend to consume more alcoholic beverages. Even with many restaurants closed or offering take-out only options we’re seeing wine sales in the United States up 10% in March. Online sales of direct-to-consumer purchases have jumped 250%.

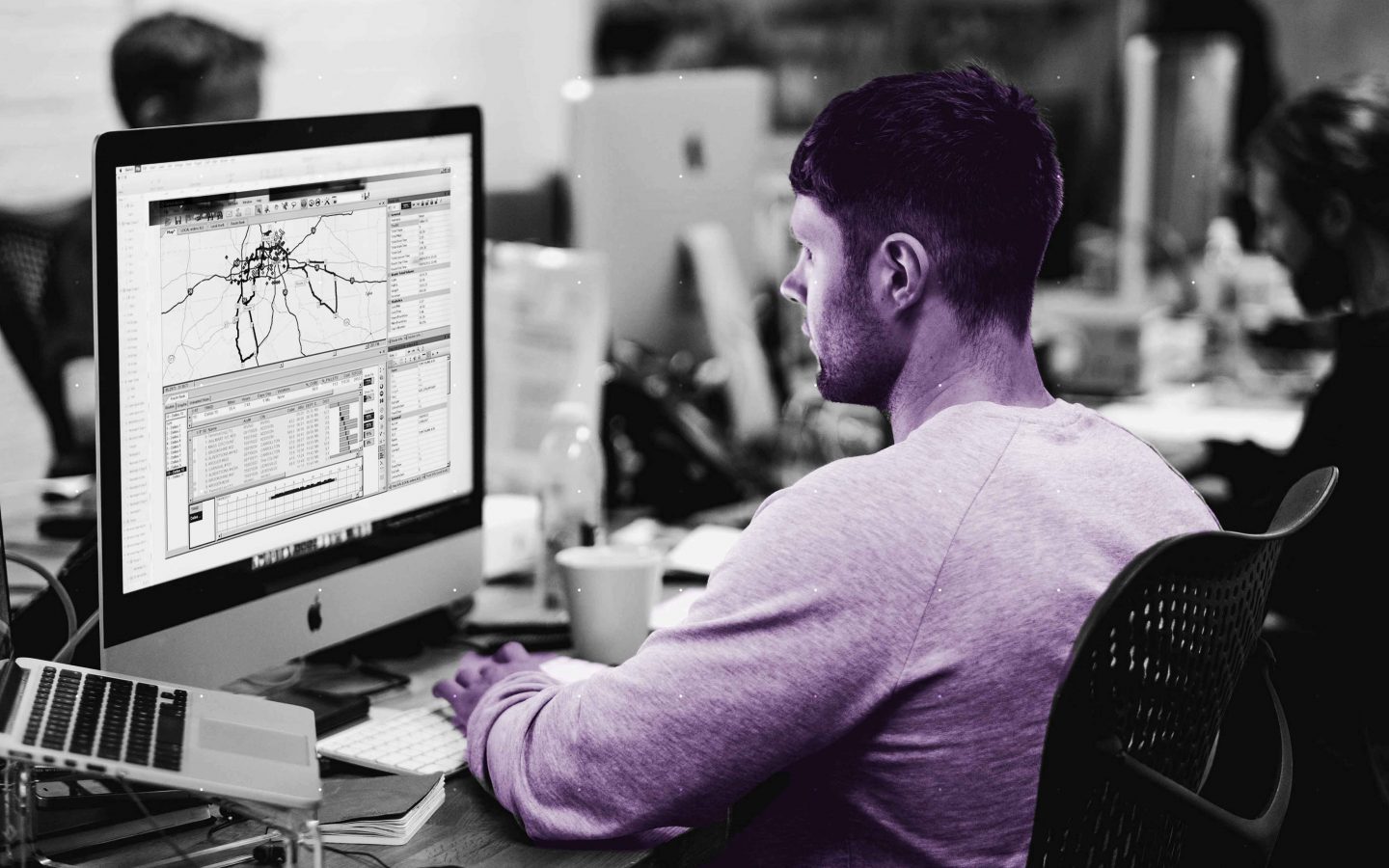

If you’re experiencing this surge, and looking at your supply chain, you’re probably adjusting your raw material procurement, trying to gauge throughout, and identifying potential bottlenecks. How are your raw material and packaging purchases changing? What logistics hurdles does a change in production volume cause you to have to jump over? Are additional ram materials available…or available but at a higher cost? Are there new import considerations you need to make?

Likely most bottlers will see a delivered cost increase in both French barrels and glass due to the rising cross of sea freight. Additionally, some wineries are facing the challenge of not having enough yield to meet the additional demand or are challenged to recruit experienced labor to capture the additional bottling opportunity. Both are bottlenecks in the supply chain.

As a supply chain professional, your ability to control costs, and eliminate bottlenecks in production can mean the difference between profitability and loss. Oftentimes, when costs increase, we can increase our price point, but we often find ourselves limited to what our market will bear. The wrong pricing decision could cost us lost revenue.

More than ever, it’s important to enter into relationships with trading partners who, like you are focused on reducing, or eliminating cost from the supply chain.